Sponsored Content

from nTopology

Healthcare providers are deploying many new technologies to improve patient outcomes, including personalized medical devices. These devices are changing the practice of prosthetics, dentistry, orthotics, veterinary medicine, orthopedics, and reconstructive surgery. Clinical studies have proven that personalized devices can improve patient outcomes and reduce the cost of care.

This article will explore the fields of medicine where personalized medical devices show great promise and how additive manufacturing can help healthcare providers maximize their potential.

What Are Personalized Medical Devices?

Personalized medical devices match each patient’s anatomy or physiology and are an increasingly important area of research in the medical field. There are many benefits to opting for personalized medical devices as an alternative to standard sizing, including:

- Shorter procedures

- Improved operational precision

- Improved functionality

- Reduced pain

- Reduced total cost of care

With the rise of additive manufacturing, often known as 3D printing, it is now possible to create personalized medical devices that are viable and economically advantageous.

Personalized Medical Device Applications

Personalized medical devices are increasingly being used across various medical fields, and each application reaps unique benefits for healthcare providers and patients.

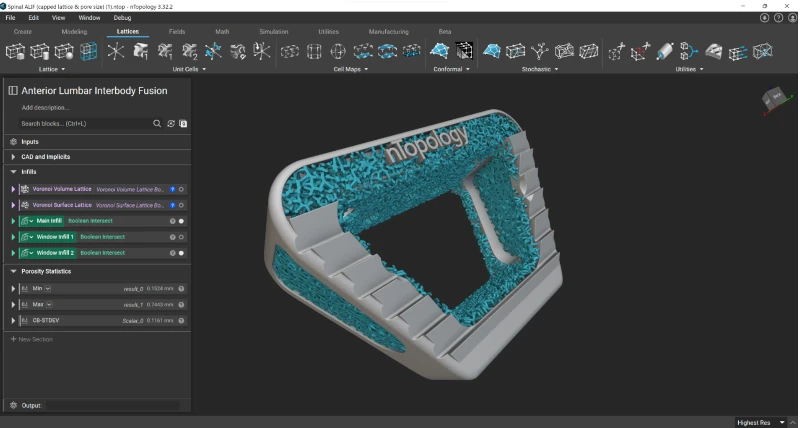

Orthopedic Surgery

While custom orthopedic implants are not new, today’s implants can be designed to match each patient’s unique circumstances and anatomy. These personalized implants can be additively manufactured with precision and shipped cost-effectively and quickly.

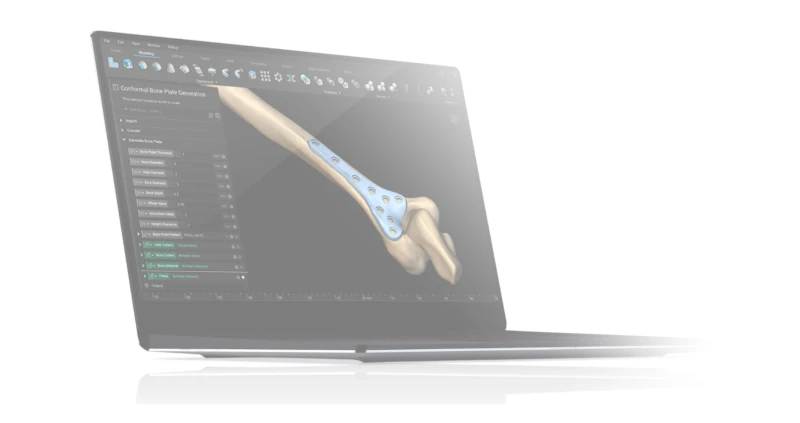

Healthcare providers often use patient-matched or personalized orthopedic implants in spinal surgery and joint replacement, usually in the knee, hip, and shoulder joints. Personalized bone plates, another important application, can treat trauma cases or promote bone fusion.

In addition to providing better alignment and coverage, personalized implants can improve fixation and mimic bone properties. They may also feature trabecular structures, facilitating osseointegration.

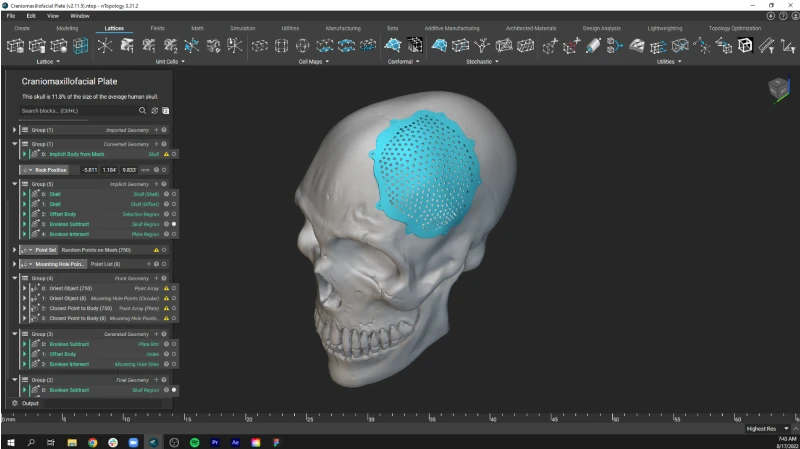

Plastic and Reconstructive Surgery

Patient-specific implants offer several benefits for reconstructive surgeons, who often deal with unique instances of traumas and deformities. These personalized implants offer excellent anatomical fit, enabling complete restoration in maxillofacial and cranial surgery. They can also reduce costs associated with postoperative infections.

Another application for personalized medical devices in reconstructive surgery is additively-manufactured 3D scaffolds combined with cell-based treatments. These offer an alternative to autologous bone grafts, and early clinical results in maxillofacial and oral surgery are promising.

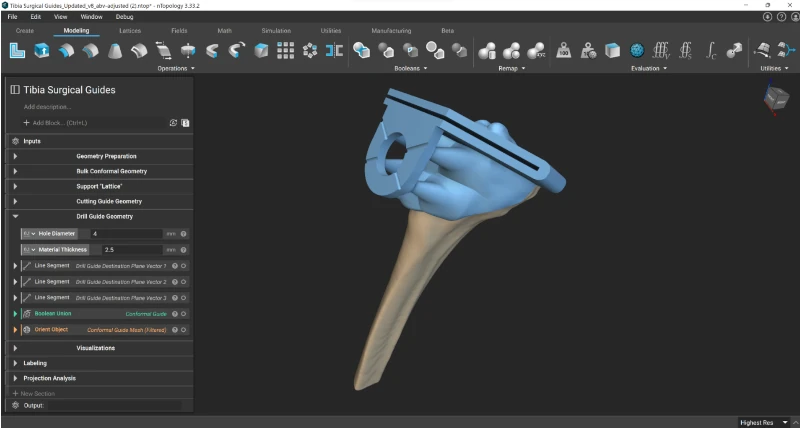

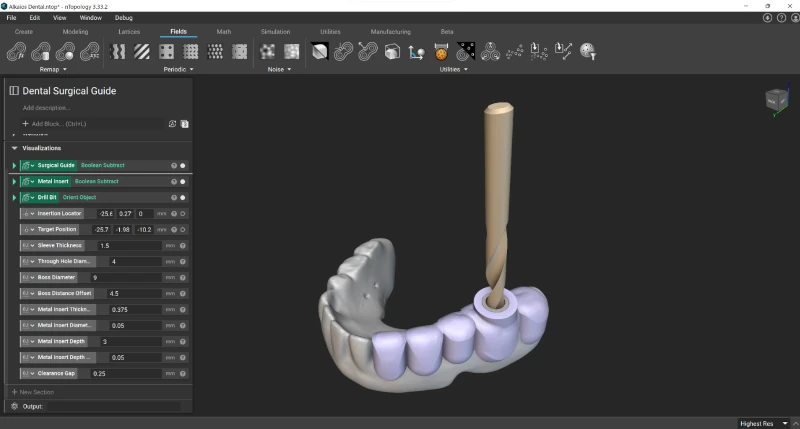

Surgical Guides

Surgical guides are critical in ensuring that operations are performed with precision, which is essential to providing good patient outcomes in reconstructive and orthopedic surgery.

Additively-manufactured patient-specific surgical guides are a cost-effective alternative to robotics-assisted surgical procedures. 3D printed guides can be prepared during surgical planning based on the surgeon’s requirements, with design features that match and conform to the individual patient’s unique anatomy.

Custom surgical guides are proven to reduce medical errors, minimize surgery times, and mitigate the need for alterations.

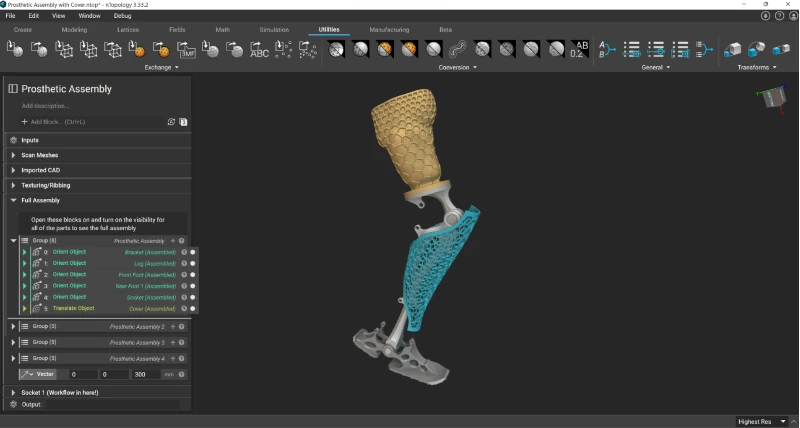

Prostheses

The traditional process for creating custom prosthetic sockets can be laborious and expertise-intensive. Customization workflows that combine 3D scanning with additive manufacturing provide a more streamlined alternative, creating lightweight sockets that offer a better fit because they more accurately represent the amputated area.

Additively-manufactured personalized prosthetic sockets are also reasonably economical, which makes them suited to children and adolescent amputees during growth.

Another benefit of additively manufacturing personalized prostheses is that you can create them with dynamic behaviors. For example, you could design the socket to be stiff where necessary but also feature flexible structures with foam-like properties for dampening and cushioning.

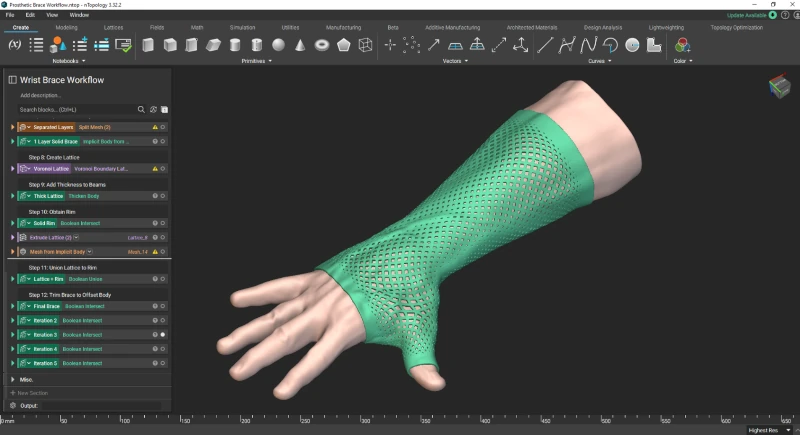

Orthoses

Using 3D scan data, you can customize orthoses, braces, and splints to offer better support and fit for patients. Like prostheses, additively-manufactured orthoses can also be designed with dynamic behaviors, such as stiff and flexible areas and perforation patterns that can improve hygiene and breathability.

Clinical studies have proven that custom hand, wrist, ankle, and foot orthoses offer similar or superior effects on kinematic and biomechanical parameters. They also score higher in comfort and user satisfaction than traditional orthoses.

Dentistry and Orthodontics

Dentistry and orthodontics are among the most digitized fields in medicine. 89% of large orthodontics labs use 3D printing technology to produce at least one type of patient-specific device.

Because dental devices require significant customization and a high production volume, digital design and manufacturing workflows are leveraged to increase throughput and streamline operations.

Dental crowns, orthodontic braces, bridges, dental models, and aligners are common personalized devices that are either manufactured directly using additive manufacturing or indirectly using 3D printed tooling.

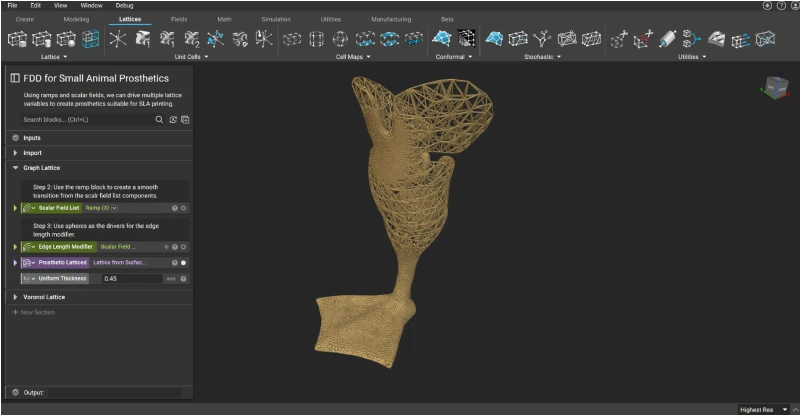

Veterinary Medicine

Many practitioners in the veterinary field are using digital workflows with additive manufacturing to create more effective, affordable, and innovative treatments for animals.

Personalized devices for animals are often used to treat pets like human patients, from creating custom prostheses to restoring bone defects with custom implants and surgical guides.

Design Software for Personalized Medical Device Design

nTopology is next-generation advanced engineering design software built from the ground up to enable you to realize the full potential of additive manufacturing. This powerful software includes design features to help you develop innovative personalized medical devices that reduce costs, improve patient outcomes, and enable personalization at scale.

Learn More

Do you want to learn more about personalized medical devices? Download nTopology’s comprehensive Personalized Medical Devices Guide to learn how to overcome the challenges of creating these devices and how additive manufacturing can help you maximize their benefits.