A team of scientists from the University of Waterloo in Ontario, Canada, has unveiled a new type of prosthetic socket that’s designed to improve fit and reduce pain in below-knee amputees. Similar to the AI-enabled smart liner developed by the London-based startup Unhindr, the Canadian device uses microfluidic actuators that subtly adjust the socket fit in response to changes in pressure and residual-limb size. It thereby automates the process of achieving comfort, replacing the interminable cycle of manually adding/removing socks.

The researchers started off with a specific focus on diabetic amputees, who often struggle to achieve optimal socket fit because of nerve damage. But socket discomfort is an equal-opportunity aggravation. All types of amputees stand to benefit from the Waterloo device.

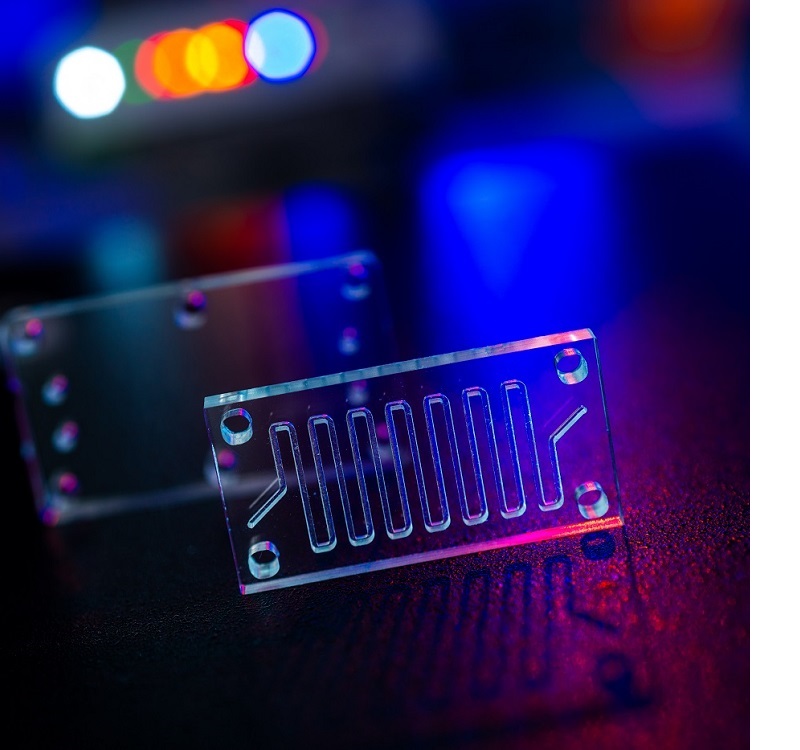

The core technology is a mircofluidic chip with 10 valves that regulate pressure in the socket. When the socket is too loose, the valves open to allow fluid into tiny channels in the socket liner, expanding the fabric to create a comfortably snug fit. In the opposite scenario, where the residual limb swells, the valves close and the socket shrinks.

The proof-of-concept study was published in the current edition of Biomicrofluidics, a research journal of the American Institute of Physics (AIP). The development team paired certified prosthetist Andreas Schirm with investigators from the University of Waterloo’s mechanical engineering department and Neural and Rehabilitation Lab. A physiatrist affiliated with the Canadian Paralympic team rounded out the interdisciplinary unit.

They based their innovation off an earlier device that uses pneumatic actuators to adjust the pressure of the prosthetic socket. While it was reasonably effective, the device was too heavy and bulky for use in real-world situations. The microfluidic device, by contrast, only weighs 10 grams (lighter than a triple-A battery) and takes up just a few cubic inches in volume. At those dimensions, it’s small and lightweight enough to be worn with a regular prosthesis without interfering with normal function.

“Rather than creating a new type of prosthetic socket, the typical silicon/fabric limb liner is replaced with a single layer of liner with integrated soft fluidic actuators as an interfacing layer,” co-author Carolyn Ren said in a press release. “These actuators are designed to be inflated to varying pressures based on the anatomy of the residual limb to reduce pain and prevent pressure ulcerations.”

As a next step toward creating a marketable product, the Waterloo team will try to further streamline the design by experimenting with varying prosthesis types and new materials for the prosthetic liner. The full study is available at AIP Biomicrofluidics (paywall protected).