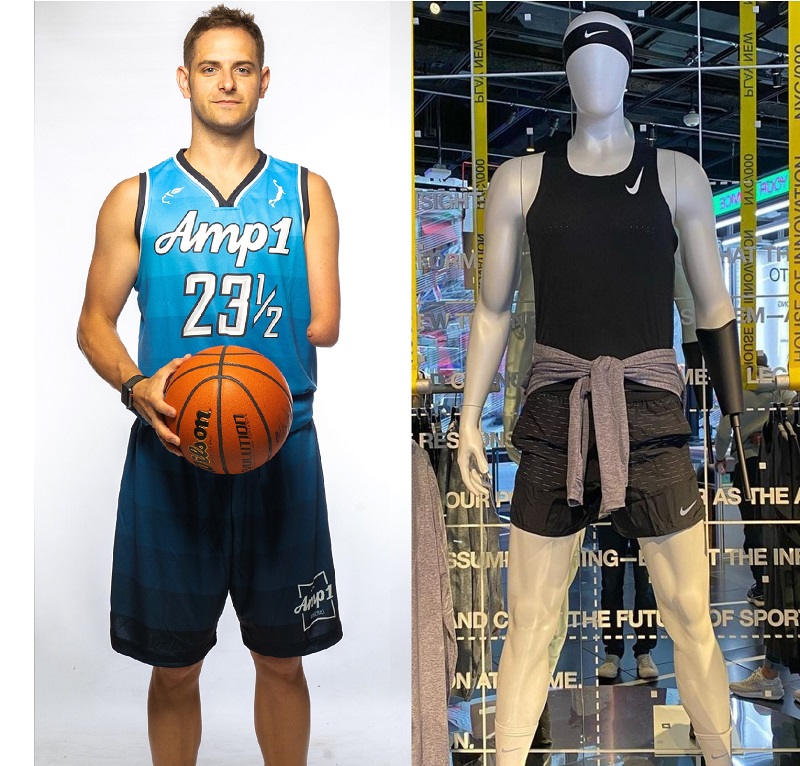

It was only by accident that we learned how Richard Ramsay played such a big role in creating and marketing Nike’s GO FlyEase. We originally contacted him with a completely unrelated, relatively trivial query about a photo of an amputee mannequin that he’d posted on his Instagram page. The photo caption read, “When @nike turns you into a mannequin. . . . .” We weren’t sure whether Ramsay meant the mannequin was literally modeled on him or if he was just goofing, so we sent a DM and asked for details. “If it’s a good story, we’ll share it with our readers,” we wrote.

When we finally got him on the phone, he said: Yeah, it’s true, I really was the model for that mannequin. Why you? we asked. How did Nike find you? So then he tells us he works for Nike, which we were not aware of—we only knew Ramsay as a player for AMP1 basketball. And then it comes out that he worked on FlyEase, one of last year’s highest-profile Nike releases, and in fact was involved almost at the very start of that nearly decade-old project. On the interview tape you can hear us kind of gulp, and then we say: “This is, like, a way bigger story than I was prepared for.”

We got the bare bones of the FlyEase saga in that initial conversation, then scheduled a followup so we could do enough homework to ask better questions. We ended up with more than 20 pages’ worth of transcript, only a few lines of which fit into our article for the Jan/Feb print edition. Here’s the best of the rest of what we learned from Ramsay about Nike, the accessible clothing industry, and universal product design (or “human design,” as Ramsay calls it). This Q+A is condensed and edited for clarity and coherence. You can follow Ramsay on Instagram at @onearmkid.

It sounds like you joined the FlyEase project pretty shortly after Matthew Walzer wrote his letter to Nike.

Yeah, that’s pretty accurate. Matthew must have written that letter in late 2012, and I came on about halfway through 2013. There had been some initial work done on a shoe very similar to this in the early 2000s, and then again in around 2008. When this letter was written, we kind of brought that up again and started from there. But we completely modified the original version to work for more people.

Help me understand how you got connected with the FlyEase team. Did they approach you because they knew you have an athletic background and you have connections in the disability community, or did you approach them?

Short answer: It was such a huge God thing. Long answer: When I got my job at Nike [in 2011], my big thing was: “How can I meet Tobie Hatfield?” Because I had all these crazy ideas of making shoes for people with disabilities, both lower-limb amputees and upper-limb amputees like myself. I remember being a 13-year-old boy in my basketball team [Ramsay starred in multiple high school sports], but my dad still had to run down to the court during games to tie my shoes. If they came untied, I couldn’t get the knot secured tight enough.

So you’re in a timeout and and your dad’s coming down to tie your shoes for you?

Not even a timeout. I’m in a dead ball, and my dad comes running down so I can meet him over on the sideline. I can vividly remember putting my foot up on my dad’s knee so he could tie my shoe for me. I don’t love being the center of attention, but when you’re in junior high and early high school and your dad is still tying your shoes for you, you’re pretty center of attention.

Around the time I started working at Nike, I tried out for AMP1 and fortunately I made the team. I would watch my teammates who were leg amputees pull out their shoehorns and struggle to shove their foot into the shoe without having any mobility in the ankle. So then I started thinking about how we can make that easier, so they can put their basketball shoes on faster and not have to get to the gym an hour early just to get their leg ready.

In other words, you had all these ideas percolating before you got involved with FlyEase. How did you end up getting Tobie’s attention?

I had a friend at the Employee Store, which is where Nike employees shop, and he knew Tobie’s niece. So he was able to reach out to set up a meeting for me and Tobie. And during that meeting, I basically started talking about all these ideas that I had. I was essentially quizzing him on how I could make some of these things happen. During this meeting, he never once mentioned that he was working on an adaptive shoe for Matthew Walzer. But about three, maybe four months later, he got in contact with me because they needed some help.

Original @onearmkid.

He brought me in, and he pulled out this shoe and showed it to me and had me try it on. I was able to put the shoe on my foot, and I was able to zip it up and strap it, and it was this overwhelming feeling of, just—I don’t know, relief. I don’t know the best way to explain it to you. It was just this realization that if I had bought a shoe like this growing up, I wouldn’t have had to go through any of that embarrassment of having my dad tie my shoes. I just realized we’re going to be able to change things for a lot of people to remove that embarrassment or remove that Othering that I had to go through.

From then on, I was really involved with FlyEase. I was a voice right there on campus that not only knew how to make shoes but also had first-hand experience—pardon the pun—with putting on shoes with one hand. I remember the very first time I sat down and chatted with Tobie about it. We just riffed for the next, probably, hour and half. I was asking questions like, “What do you think about this?” and “Have you thought about that?” That was the start of a forever friendship with Tobie. He didn’t have a lot of familiarity with disability, and I think that’s why he had no problem bringing me in. He’s never lived a life with one hand, and I have. So whatever experience I had from disability, Toby didn’t. And whatever experience I didn’t have in terms of developing a product, Toby did. It was a perfect relationship.

Do you remember any of the specific design challenges you were wrestling with back then?

We were talking about the fastest way to get shoes on and off. That worked very well with Tobie’s ideas, because the back of the shoe opens up so you can just slide your foot in. And then we looked at, once the shoe is on the foot, how can you get it tightened up so it doesn’t feel like it’s just flopping around at the bottom of a prosthesis? That’s where the strap came into play. And then the next thing was how you make the shoe look like a “normal” shoe without having that medical connotation.

Did he incorporate some of the ideas you shared with him into the design of FlyEase?

Not all of them, but some of them did happen. In fact, a couple of the ideas that I had were patented through a program we run at Nike. We’re still in the process of working through some of them, so that’s as much as I can say about it for now.

In addition to Tobie and me, there was also someone named Sarah Sowers. She was the business brains behind the operation. She was the one that was trying to make the connection between doing this product for one person and getting it into Nike’s actual product line. Sarah was not working on the specific product, but she was the one behind the scenes asking, “How can we bring this to retail so we can offer this product to other people who also struggle to put their shoes on, but who haven’t necessarily written Nike a letter?”

The three of us pulled and pushed, and pushed and pulled. We not only made Matt Walzer some shoes that he could he could wear when he went off to college, but we also finagled our way into making three different colorways of about 2500 pairs each. Those sold out, so then we got the [Nike] basketball [shoe] team to bring this product to market, and that was in 2015. And then from there, it was well received by not only the adaptive community, but also by parents who were just looking for an easier way to put their kids’ shoes on. We started hearing, “Can we get smaller sizes? Can we get a woman’s version? Can we get different colors? We need more of this product, why why can’t we get more of it?” And that turned into this hurry-up offense to bring these products to the market. It’s not like you just snap your fingers and all of a sudden these shoes show up. They take time. We got a kid’s version to the marketplace in maybe five months, which is really fast. Then all of a sudden we’re in running shoes, and then we’re in core performance, and then our price point-conscious basketball shoes.

When you think back to that time, were you aware of any cultural shifts that were making the whole culture more receptive to accessible design?

I think the big shift was social media. I say that because I no longer had to search high and low to meet other amputees. I could get on Twitter or YouTube or Facebook and type in “amputee,” and I could see thousands and thousands of posts from all over the world, all in real time. And I would say that really changed the accessibility movement for the better. It was just this perfect storm of how we can all be connected, and that played into the human need not to feel alone.

What’s the connection between FlyEase and the limb-different mannequin you posted on Instagram?

Starting in about 2018, our team started talking about changing the way people view role models. We thought it would be pretty easy to start with mannequins and make them in a range of body types, instead of all of them reflecting a body that’s 6’2”, 200 pounds of pure muscle. So our team started working on getting these mannequins made. We were not only able to get plus-size mannequins into a lot of our stores, but we were also able to get wheelchair-using mannequins, leg-amputee and arm-amputee mannequins. And because I was part of FlyEase, that mannequin is technically built after me.

So it really was you? Because I thought you were serious when I first saw your Instagram post, but after I looked at it again and read the comments I decided you were just kidding around.

No, it literally came from a picture of me. But only the people on the team would ever know.

Any news you can share about future innovations in FlyEase?

Yeah, there are a couple of things. There’s going to be a bunch of kids’ FlyEase product coming out beginning in the spring of 2022, and basically continuing for five years. It’s going to be very heavy within the kids’ category, which is phenomenal. There are a few woman-led initiatives around FlyEase, taking very popular Nike models and adding a hands-free, or a 90 percent hands-free, solution. They’re going to be shoes that you only have to tie one time, and then you can take them on and off without ever touching them again.

There’s a third one that will basically be a brand-new creation. We don’t even have a final design of it yet. That’ll come in the summer of 2023. And from there we also have a couple of new basketball models, one of which will be specifically made for Elena Delle Donne. She’s the best player in the WNBA, and she’s a huge advocate for the adaptive community because she has a sister who has disabilities. Her big push to Nike was: “I want a shoe that I can compete in professionally to the best of my ability, and I want that same shoe to be able to be worn by my sister.” Her sister is in her early forties, and until we created her a shoe a couple of years ago, she had never put a shoe on by herself.

Now that you’ve conquered the hands-free-shoe summit, is there another peak in your sights?

I want to specifically focus on the area of human design or universal design—how can we make products that are accessible for everyone no matter where you are on the ability spectrum? Tobie Hatfield calls everyone “temporarily able-bodied.” When you think about the life-cycle of a person, we can’t do much on our own when we’re born. Then we gain the ability to do more and more on our own, and then we age and we start to lose some of our abilities again. And at any stage in their life, you never know when a person may be in a “disabled” body. Maybe you’re coming off an injury and you’re in your [physical] prime, or maybe you’re a great-grandfather—it doesn’t matter. At some point, universal design is going to make your life better.